Before reading this article, ensure you have read Measurement - Parts & Labour and Using Formula within Groundplan articles to aid in understanding the following Formula examples.

- If there is more than one roof pitch required on the Project, each pitch must be a separate Measurement with the correct Formula, Parts and/or Labour applied.

- The Roof Pitch Chart will assist with common roof pitches.

- Find the secant of a slope using a scientific calculator.

📝 The Formula values provided in this article are for example purposes only.

| Term | Explained |

|---|---|

count |

total counts |

len |

total metres measured |

area |

total square metres measured |

count, len or area / x |

total count/length/area divided by an amount |

count, len or area * x |

total count/length/area multiplied by an amount |

ceil(x) |

rounding up a decimal value to the next whole number |

Roofing

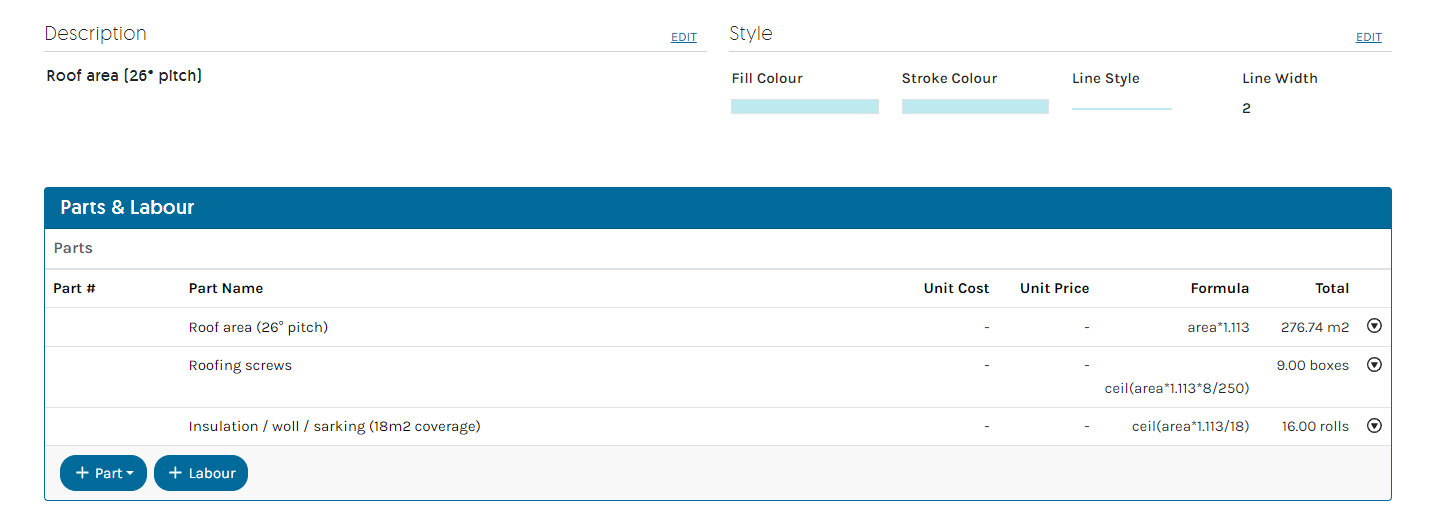

Example Parts for Roof area (26° pitch) using an Area Measurement:

| Part | Explanation | Formula | UMO |

|---|---|---|---|

| Roof area (26° pitch) | The area measured multiplied by the roof pitch |

area*1.113 |

m2 |

| Roofing screws (8 per m2) | How many screws are required for the area measured multiplied by the roof pitch and allowing for 8 per m2 divided by 250 screws in a box |

ceil(area*1.113*8/250) |

boxes |

| Insulation / wool / sarking (18m2 coverage) | How many rolls are required for the area measured multiplied by the roof pitch divided by based on 18m2 coverage |

ceil(area*1.113/18) |

rolls |

Guttering

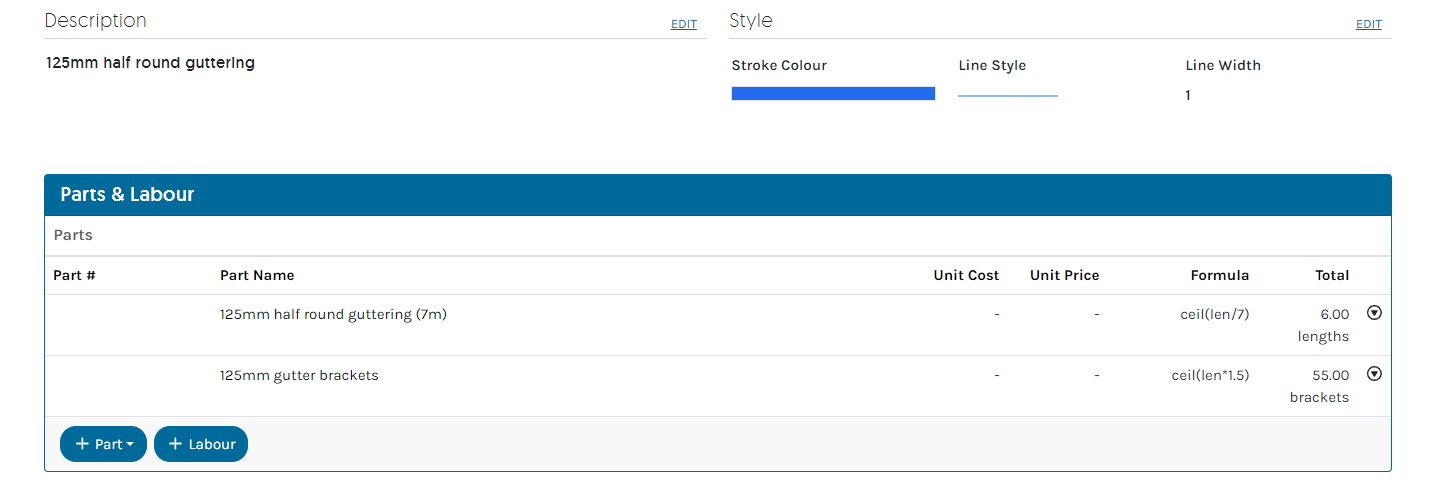

Example Parts for 125mm half round guttering Length Measurement:

| Part | Explanation | Formula | UMO |

|---|---|---|---|

| 125mm half round guttering (7m lengths) | How many 7 metre lengths are required of 125mm half round guttering |

ceil(len/7) |

lengths |

| 125mm gutter brackets | How many gutter brackets are required for the length measured divided by 1.5 metres intervals |

ceil(len/1.5) |

brackets |

Downpipe

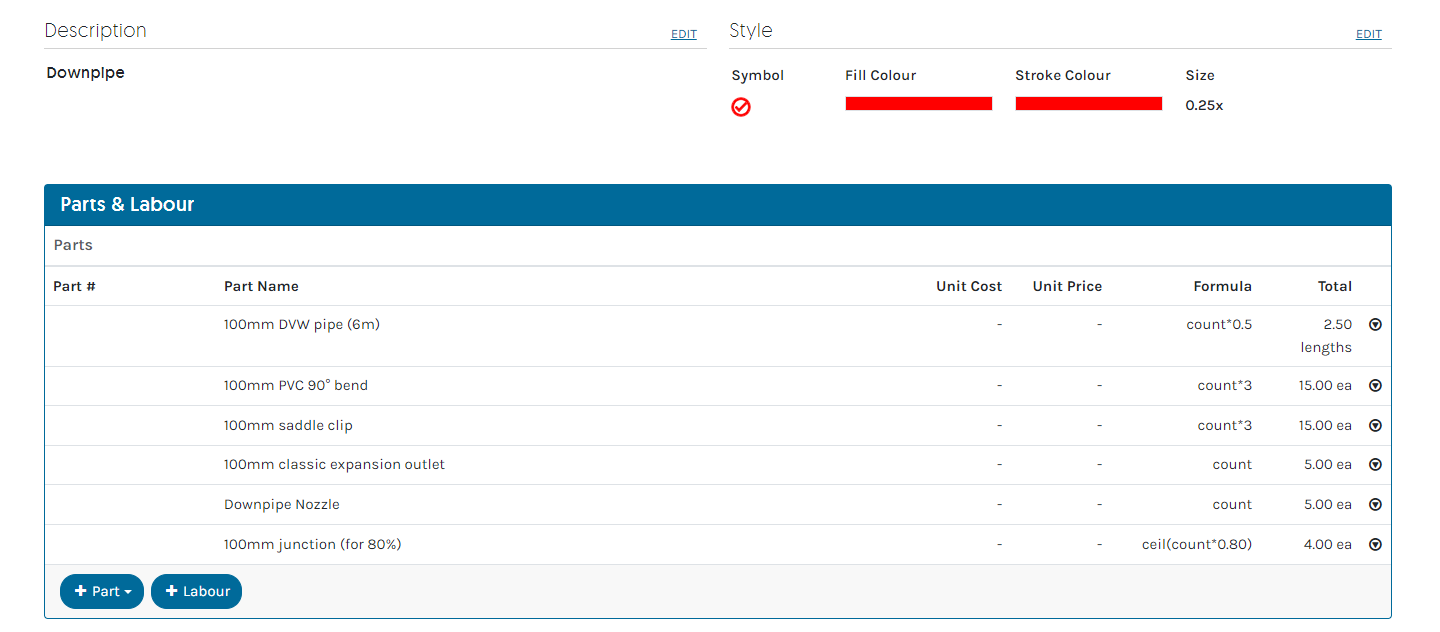

Example Parts for a downpipe Count Measurement:

| Part | Explanation | Formula | UMO |

|---|---|---|---|

| 100mm DVW pipe (6m) | How many 6m lengths are required to complete downpipes when 3 metres 1/2 length (3m) is needed for each downpipe |

count*0.5 |

lengths |

| 100mm PVC 90° bend | How many 90° bends are required when 3 are needed for each downpipe |

count*3 |

each |

| 100mm saddle clip | How many saddle clips are required when 3 are needed for each downpipe |

count*3 |

each |

| 100mm classic expansion outlet | How many expansion outles are required for each downpipe |

count |

each |

| Downpipe nozzle | How many nozzles are required for each downpipe |

count |

each |

| (optional) 100mm junction (for 80%) | How many junctions required for 80% of the downpipes needed |

ceil(count*0.80) |

each |

For Formula assistance, please reach out to Support. Go to: Help > Send us a Message.

Download a PDF copy of Using Formulas within Groundplan here.

Organise your session today! Click Help > Send us a Message and ask to book in for free training.

Trainers can assist with:

- Workflow solutions

- Time-saving tips

- Making sure you're getting the most out of your subscription

If you've accessed your free training and need further Support, reach out to book a 1 or 2 hour paid session.